Kinematic holders, powder 3D printers, single crystal growth systems and much more in review of Photonics 2025 exhibitors

We present to your attention a review of products to be displayed at Photonics. World of Lasers and Optics 2025 at EXPOCENTRE Fairgrounds on 1–4 April 2025. You can see a preliminary list of exhibitors on the exhibition website.

A competitor to European and American optomechanical giants

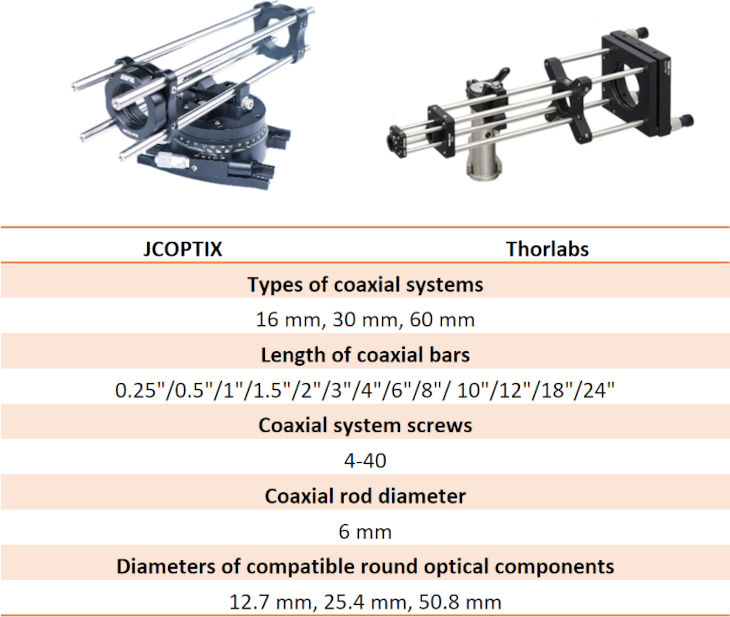

INSCIENCE has tested JCOPTIX optomechanical components together with the laboratories of ITMO, LETI, and MEPhI universities. The tests showed not only stability similar to Thorlabs, Optosigma, and Newport components, but also their full compatibility.

The KM100 Thorlabs kinematic optics mount is designed for two-axis angular adjustment of 1” diameter optical components in the range of ±4° with an accuracy of 0.5°/turn, the competitor of the MMM-1 JCOPTIX surpasses the European analogue with an accuracy of 0.38°/turn. JCOPTIX components for 16, 30 and 60 mm coaxial systems completely repeat the assortment and size range of Thorlabs, which also simplifies integration into already built systems. JCOPTIX standard linear translators are equipped with Mitutoyo precision micrometer screws, which allows you to not compromise on the usual accuracy when choosing this manufacturer.

Photo: INSCIENCE

Photo: INSCIENCE Photo: INSCIENCE

Photo: INSCIENCE Photo: INSCIENCE

Photo: INSCIENCEOptical and optomechanical components of JCOPTIX are used in experiments by researchers from leading Russian universities. The research areas include spectroscopy, interferometry, quantum communications, laser technologies, and plasma analysis.

The key advantages of JCOPTIX are strict quality control, order processing speed, large warehouse stocks, and flexibility in manufacturing non-standard solutions.

These and other JCOPTIX products can be seen at the INSCIENCE stand FF050 at Photonics. World of Lasers and Optics 2025.

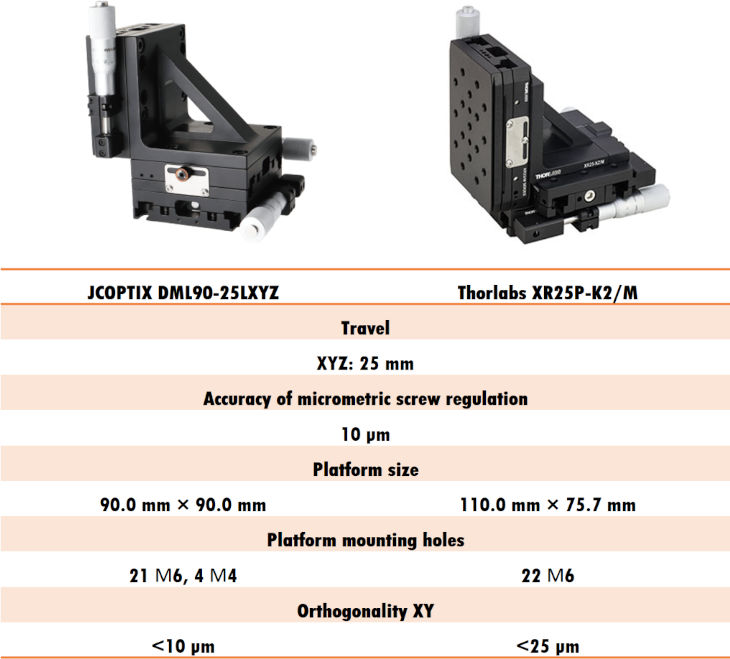

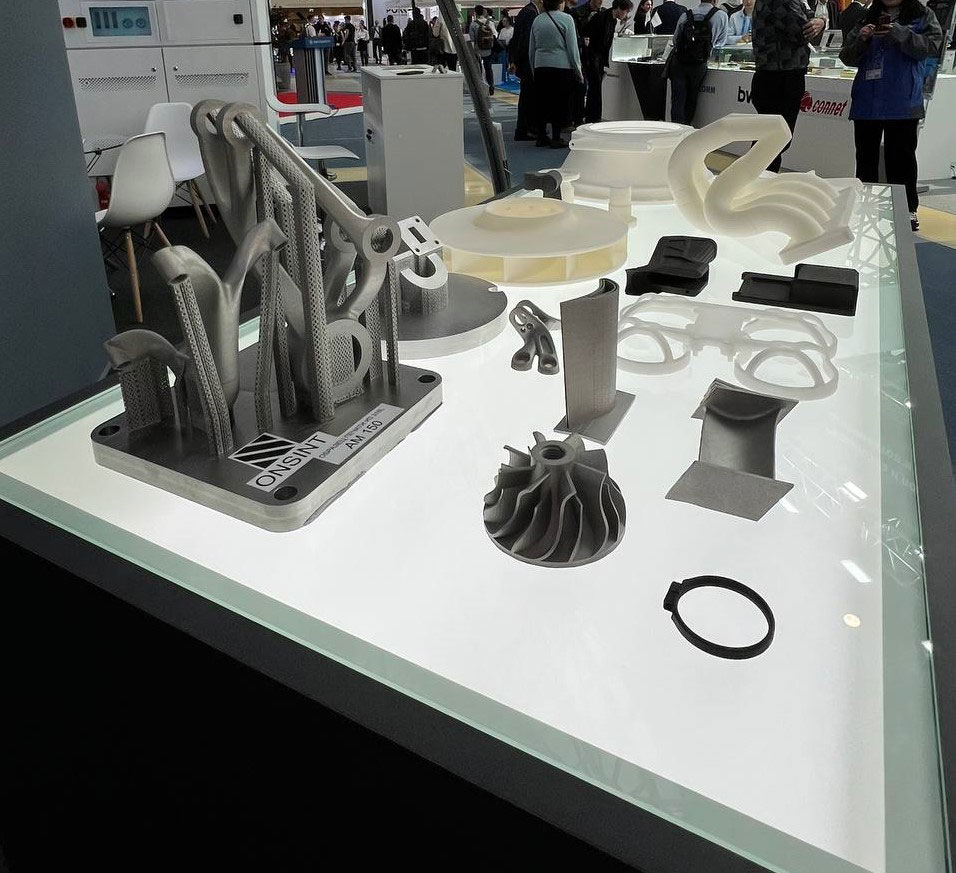

ONSINT, a Russian developer and manufacturer of industrial 3D laser powder printers based on SLS and SLM technologies

Photo: ONSINT

Photo: ONSINTA key objective of the company is projects defined by the Strategy for Scientific and Technological Development of the Russian Federation, aimed at the transition to advanced technologies for the design and creation of high-tech products (the Executive Order of the President of the Russian Federation No. 145 dated 28.02.2024).

ONSINT equipment operates in many regions of Russia, including Moscow, Tomsk, Belgorod, Sverdlovsk, Novosibirsk, Kaliningrad, Volgograd regions, Krasnodar, Krasnoyarsk and Perm territories, Udmurtia, Bashkortostan, and the Lugansk People's Republic.

ONSINT technologies help achieve strategic tasks set by the Defense Ministry under state defense orders. The company provides comprehensive support in achieving the best results in the aerospace industry, fuel and energy sector, mechanical engineering, instrument making, microelectronics, medicine, science and education.

Photo: ONSINT

Photo: ONSINTThe company’s competencies allow it to accommodate needs of partners at every stage of production, from developing a product and testing its prototype to organizing production cycle and embedding the product in the production chain. Equipment maintenance is provided by qualified specialists during a long warranty period, and, if necessary, a post-warranty period. Our additive technology center (ATC) allows contracting product parts made of polymer and metal powder materials.

The company will present industrial 3D printers for printing metals and plastics, as well finished printed products for various industries at its booth FD060 at Photonics. World of Lasers and Optics 2025.

NPO GKMP Group of Machine Building and Instrument Making Companies

- the largest Russian manufacturer of industrial vacuum, testing and, thermal equipment

- a leader in research and development in the field of natural and technical sciences

- a Russian manufacturer of high-tech equipment for thermonuclear fusion, cryogenic complexes and thermal vacuum equipment for testing

The company is the successor and continuer of the traditions of the Bryansk Engineering School, specializing in vacuum physical and thermal equipment. It develops and manufactures equipment for the electronics industry, including crystal growing units.

The quality management system of NPO GKMP is certified by GOST R ISO 9001-2015 standard, which is proven by compliance certificates.

The team of specialists of NPO GKMP fulfills the most complex scientific, technical and experimental design tasks. The company's innovative projects are successfully used at leading national enterprises.

Over the years, the company has won numerous awards both at the local and federal levels.

Installations for growing sapphire and ruby single crystals by Bridgman-Stockbarger method

Designed for growing leucosapphire and ruby single crystals in any crystallographic orientation, including the C-orientation (0001). Crystals are grown in a crucible, the size and shape of which determine the size and shape of the future crystal. The Bridgman-Stockbarger method grows crystals along any crystallographic axis, which allows for a significant increase in the yield of the usable product and a reduction in the cost of subsequent processing.

Photo: NPO GKMP

Photo: NPO GKMPInstallations for growing leucosapphire single crystals by Kyropoulos KY method (Musatov, GOI)

Designed for growing leucosapphire single crystals from a melt. The Kyropoulos method is characterized by small temperature gradients at the crystallization front. The main advantages include the technical simplicity of the process and the ability to grow large crystals (>500 kg) with a low dislocation density.

Photo: NPO GKMP

Photo: NPO GKMPInstallations for growing gallium arsenide (GaAs) and indium arsenide (InAs) single crystals

Designed for growing gallium arsenide (GaAs) and indium arsenide (InAs) single crystals. The growth is performed by the Czochralski method with liquid encapsulation of the melt (LEC).

Photo: NPO GKMP

Photo: NPO GKMPVacuum gate valves

The gate valve body is a sealed vacuum chamber flanged to the vacuum system. Unlike vacuum valves, the plate of a slide gate valve moves perpendicular to the gas flow, which ensures its maximum conductivity in the open position. Therefore, vacuum gate valves are best suited for equipment operating in the molecular gas flow mode, such as turbomolecular, ion-heteric and cryogenic pumps.

Vacuum gate valves can be equipped with a manual, pneumatic or electromechanical drive. Gate valves can be made with a bellows or elastomer stem seal.

Photo: NPO GKMP

Photo: NPO GKMPVacuum Furnaces

Vacuum furnaces are specialized thermal equipment used for thermal processing in a non-oxidizing environment and/or in vacuum. Industrial vacuum furnaces are used for thermal processing and melting.

Photo: NPO GKMP

Photo: NPO GKMPMembrane compressor

The compressor is used to increase the pressure of the working gas before entering the process equipment.

Photo: NPO GKMP

Photo: NPO GKMPProducts made of refractory materials and alloys

Custom-made products and parts of any complexity made according to customer drawings of refractory materials - tungsten, molybdenum and their alloys, heat-resistant ceramics based on zirconium dioxide, aluminum oxide, boron nitride, silicon carbide and their alloys. Large-scale production.

Tungsten products Molybdenum products High-temperature ceramics.

Photo: NPO GKMP

Photo: NPO GKMPYou can see the available equipment and get professional advice from experienced specialists at the NPO GKMP stand FK010

We are looking forward to seeing you at Photonics. World of Lasers and Optics 2025 at Forum Pavilion of EXPOCENTRE Fairgrounds on 1–4 April 2025. Get your personal visitor ID.